Ultrasonic Application

The equipment for ultrasonic cleaners includes a generator, a transducer and a stainless steel tank. The transducer introduces high frequency sound waves into the liquid media. Each point in the liquid is subject to alternating negative and positive pressure as the sound waves pass by. Negative pressure causes the liquid to fracture creating cavitation bubbles. As negative pressure is replaced by positive pressure, cavitation bubbles implode, creating intense areas of pressure and temperature.

It is accepted that the intensity and amount of cavitation in a given volume of cleaning solution will determine the degree of cleaning. For each cleaning operation there are variables that will affect cavitation intensity, including the type of cleaner, bath temperature, the workload, power input to the transducer and the transducer’s frequency of vibration.

Transducers generally operate between the frequencies of 20–40 kHz, dependant on the type of transducer construction. Low frequencies (17-25 kHz) produce large vapour bubbles and powerful implosions for cleaning large work surfaces. Frequencies that are too low can damage fragile components; for this reason the electronics industry uses frequencies greater than 35 kHz. Also, the noise generated at the lower frequencies may be objectionable.

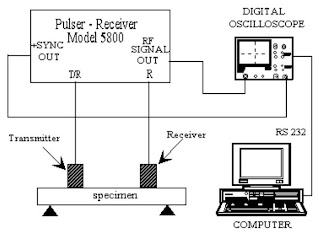

Ultrasonic System

In some instances the transducer frequency may be varied ± 3 kHz from the nominal frequency. This technique eliminates the tendency for cavitation to occur in discrete layers, leaving layers of less cavitation in between. Special ceramic transducers can generate six different frequencies in the tank at the same time. The high frequencies produce small vapour bubbles that penetrate small crevices and loosen contaminants, while the large bubbles formed at low frequencies remove soils completely.

Tidak ada komentar:

Posting Komentar